Understanding Humidity Monitoring in the Data Center

Environmental monitoring and control in the data center are usually assumed to be synonymous with temperature control—how to make sure the air is at...

3 min read

![]() Packet Power Team

:

Jul 14, 2022 7:45:00 AM

Packet Power Team

:

Jul 14, 2022 7:45:00 AM

![Proper Placement: Installing Server Room Environmental Monitors [VIDEO]](https://www.packetpower.com/hubfs/Blog/Packet%20Power_%20Environmental%20Monitor.jpg)

You have a significant investment in your IT infrastructure and you want to get the most out of that investment by extending equipment life, optimizing usage, and lowering your operational costs. You can get the data to help you accomplish these goals by properly placing modern, high-tech temperature and humidity monitors in your server room.

First, it’s important to know the proper temperature and humidity ranges at which servers will function best. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) suggests both a recommended and an allowable range for air temperature entering into a rack of servers.

In terms of humidity, ASHRAE recommends data centers and server rooms have:

Good monitoring solutions are flexible because needs change. There is no perfect solution and the right one for you will depend heavily on the layout of your facility. However, finding hot spots may be your first priority. Walking around the facility to detect hot spots may seem sufficient, but it is time-consuming and lacks actual data to inform your planning.

A hand-held meter (temperature gun, strips, or a forward-looking infrared device) will give you hard numbers that you can react to immediately. But it still requires someone manually inspecting your facility on a regular basis over time in order to spot trends. This is why automated monitors are superior for long-term operational improvement.

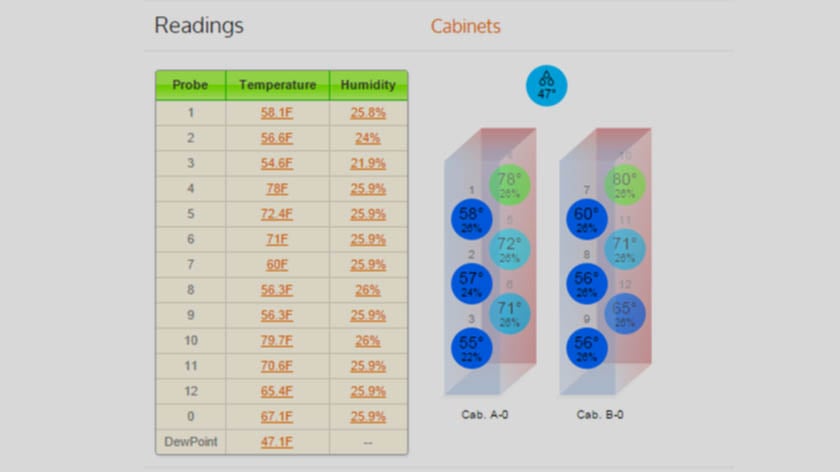

Collecting data both from individual cabinets or racks as well as the ambient room conditions will give you the best data to make decisions.

The size and shape of the space will help determine the best approach for room-wide monitoring. At a minimum, you want monitors close to the door, close to the thermostat controlling the room, near the middle of the room, and at the furthest point away from the door to track overall temperature and humidity levels. You can monitor the status (and effectiveness) of cooling devices by placing monitors next to HVAC units or vents and in each air circulation plenum space.

For even better coverage, think about where there are notorious hotspots in your server room (maybe at the end of a row or in the very middle) and place extra monitors in those locations.

Typically, the number of temperature points to measure in a rack depends on how granular you want your data, the number of servers per rack, and rack spacing.

ASHRAE recommends six sensors per rack placed at the top, middle, and bottom of both the front and back of each rack. This recommendation captures the air intake as it enters the rack (bottom front), works through the rack (middle), and exits (top rear). This level of detail will give you a virtual map of every rack or cabinet in your server room.

Packet Power's E306 monitor allows for up to six temperature probes so you can easily follow the ASHRAE recommendations.

It's not uncommon for air to increase by as much as 20°C (35°F) from where it enters a rack to where it comes out. Three sensors instead of six may be sufficient for many cabinets or racks. Knowing that the top rear of a rack or cabinet is often the hottest spot, you'll want to ensure you have coverage there. If you have closed cabinets in a tight space, additional sensors help identify any specific trouble areas. If your server room has open, spaced out racks, those racks may warrant only 3 sensors.

Avoid placing temperature sensors meant to measure conditions within a rack next to where there is direct airflow and you will get better data.

Because humidity levels do not change as quickly as temperature, you do not need as many monitors tracking moisture as you do heat. For minimal humidity monitoring coverage, plan on one sensor in the middle of each row. For better coverage, place one humidity sensor every five racks (in front of the middle of the five). For maximum coverage, place one humidity sensor in front of every three racks.

Packet Power developed wireless environmental monitors to meet the needs of hyperscale-sized data centers. Smaller operations and many businesses with their own server rooms are also choosing Packet Power sensors. The wireless monitors track 1-6 temperature points per monitor along with relative humidity. Their compact size fits in even the smallest spaces and they install in minutes.

This short video demonstrates just how easily and quickly our environmental monitors are to install.

Some Packet Power environmental monitors require AC power and some operate on batteries. The monitors should be placed no more than 30 meters from a Gateway or another AC-powered Packet Power device. Once a monitor is installed it will automatically join the wireless mesh network and begin transmitting data. No field configuration is needed.

Once you have the temperature and humidity data for your facility, you can begin to analyze and optimize your HVAC system usage. Packet Power offers environmental monitors to track differential air pressure providing insights on airflow as well. Use this information to help optimize your cooling strategies.

If you’d like help getting started adding environmental monitors to your building, please contact us.

Environmental monitoring and control in the data center are usually assumed to be synonymous with temperature control—how to make sure the air is at...

![Using Temperature Sensor Data to Drive Business Decisions [VIDEO]](https://www.packetpower.com/hubfs/Blog/using%20temp%20sensors.jpg)

To make the best business decisions around temperature and energy use, you need to have the data points. Advances in sensors and wireless technology...

Are controlling air conditions and knowing how wet the air is important to your business? Then humidity sensors are a must. Also called hygrometers,...