Proper Placement: Installing Server Room Environmental Monitors [VIDEO]

You have a significant investment in your IT infrastructure and you want to get the most out of that investment by extending equipment life,...

4 min read

![]() Packet Power Team

:

Aug 4, 2022 10:25:00 AM

Packet Power Team

:

Aug 4, 2022 10:25:00 AM

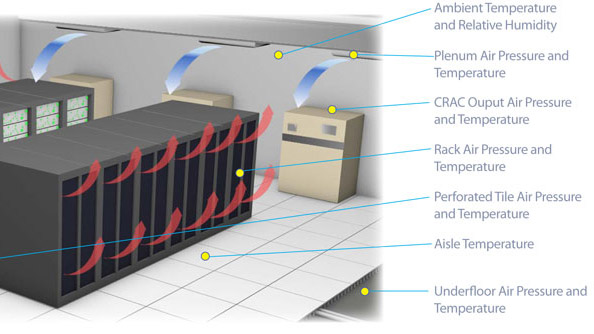

Properly cooling a data center is not straightforward. Cold air is one of the most valuable commodities in data center operations. However, optimizing airflow and cooling is challenging without a good map of air movement through your data center. By using differential pressure sensors, it becomes easy to get a clear understanding of the airflow patterns throughout your data center. The cost and ease of implementation can translate to an ROI in as little as one month. Safely raising the ambient temperature by as little as one -degree can reduce energy costs by 4-5%.

Understanding differential pressure zones and airflow allows you to:

Using Packet Power's environmental monitor with a differential pressure sensor, you get comprehensive, real-time data on temperature, humidity and differential pressure. The monitor can be placed in strategic locations. Installation is further simplified with all monitors automatically connecting to the Gateway. No expertise is required as the network is self-configuring and data can be viewed immediately on Packet Power’s EMX Portal or integrated into any BMS or DCIM.

Differential pressure is valuable in monitoring the efficiency of airflow or cooling through a facility. It is important to note that differential pressure is not a measure of airflow, but rather the air pressure that drives the airflow, specifically the difference in air pressure between one area and another.

If the differential pressure between two areas is high, that means that the flow rate of air between the high pressure and low pressure area will be faster. It does not tell us the volume of air flow, only the force.

Differential pressure can be a useful indicator when trying to optimize cooling systems and balancing airflow. Changes in differential pressure validate improvements in airflow such as better sealing of underfloor tiles or racks. It can point out unseen changes in air handling performances that may otherwise go unnoticed (i.e. a decreased differential pressure can be caused from leaks, fan performance, or obstructions).

Being able to observe differential pressure in key parts of the data center, enables airflow to be better understood, contained and directed, creating a more efficient and reliable environment.

You can use machine-learning, AI-powered software systems to crunch the data from your Packet Power environmental monitors and get suggestions for system design changes that can reduce the amount of cooling you need to do. Some of these options will even communicate directly with your hardware to make changes without staff intervention.

To install a differential pressure sensor, find two areas with different air pressures; an area with higher air flow will always have a different pressure to an area with a lower flow rate (i.e. inside an air plenum versus outside an air plenum). Typical areas for monitoring differential pressure include:

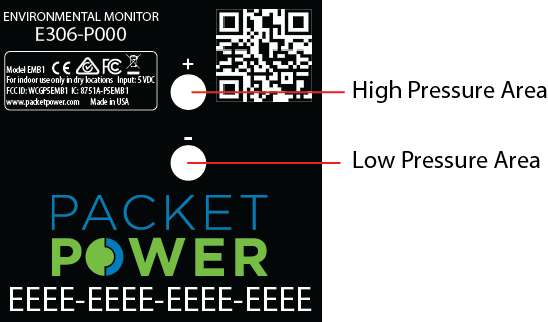

Getting differential pressure data from Packet Power's E306 monitor is simple. Place one of the sensing tubes in a higher pressure zone like the base of a server cabinet by the air intake. Place the other tube in an ambient area with little airflow like the top of exterior of the server cabinet.

Note the area monitoring the higher pressure (or faster airflow) should use the tube marked with the (+) positive symbol. The area with the lower pressure or slower flow should use the tube marked with the (-) negative symbol.

The resulting pressure differential will be indicative of the degree of airflow coming through the cabinet. Differential pressure is expressed in Pascals (±500 Pa in 0.2Pa or ±3% accuracy). Remember that this is not a measurement of airflow but rather a relative indication. A lower differential pressure will indicate a lower airflow rate. A higher differential pressure value indicates a higher flow rate between the high and low pressure areas. Airflow and thermal management goes beyond the scope of this article which is intended as a quick overview.

Packet Power's environmental monitor also allows up to six temperature points to be monitored via remote probes. Adding temperature measurements is an easy way to determine the cooling effectiveness of airflow changes. All measurements can be viewed on the local LCD display of the monitor, or obtained via Modbus TCP/IP or SNMP through the Gateway (integrates with any BMS or DCIM), or via the Packet Power EMX Portal.

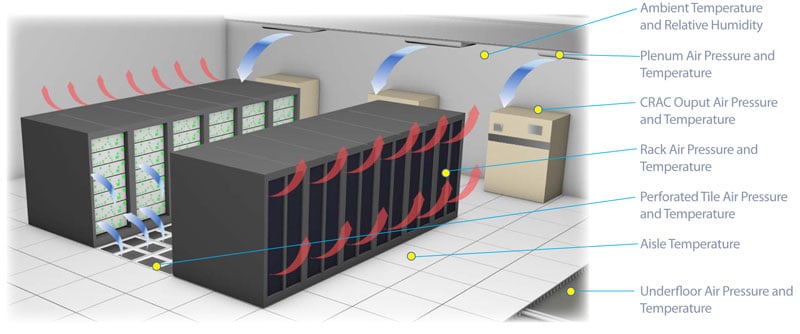

Penum air flow with baffle: The effect of baffle flow control can be monitored using a high pressure tube placed on the source side of the baffle and the low pressure tube on the opposite side of the baffle. A change in differential pressure indicates the effect of the baffle position or changes in the volume of air flow if the baffle position does not change.

Plenum air flow: Plenum air flow can be measured relative to ambient air. The high pressure tube is placed inside the plenum with the low pressure tube in the ambient air. An increase in differential pressure indicates a higher flow rate through any vents (assuming all vent openings remain the same).

Underfloor perforated tile: Placing the high pressure tube underfloor in the proximity of the perforated tile, and low pressure tube above the floor, the differential pressure will indicate the force of air through the floor tiles. Having a higher differential pressure will increase the flow through the perforated tiles. The pressure reading can assist in identifying leaks and confirming the effectiveness of improved underfloor air handling.

Server rack air flow: Measuring the differential pressure between the inside of the server rack and outside the rack (away from direct air flow such as the top exterior of the rack) can indicate changes in the airflow to the rack. A change in differential pressure can indicate a decrease in the pressure of the airflow into the rack assuming the perforations or air flow channels have not changed. Likewise an increase in differential pressure can indicate a higher air flow rate (again assuming no change to the air path). Since the EM3 support up to six remote temperature probes, it is possible to correlate the change in air pressure with changes in cooling performance, monitoring both the hot and cold zones of the rack.

![Proper Placement: Installing Server Room Environmental Monitors [VIDEO]](https://www.packetpower.com/hubfs/Blog/Packet%20Power_%20Environmental%20Monitor.jpg)

You have a significant investment in your IT infrastructure and you want to get the most out of that investment by extending equipment life,...

![Installing Packet Power Environmental Monitors [VIDEO]](https://www.packetpower.com/hubfs/Blog/Packet%20Power_%20Environmental%20Monitor.jpg)

Monitoring the environmental conditions (temperature, humidity, and differential air pressure) anywhere is a breeze with Packet Power devices. They...

Hot spots in a data center must be closely monitored: let the warmest areas in your facility get too warm and you risk degraded performance, outages,...